PowerBlast

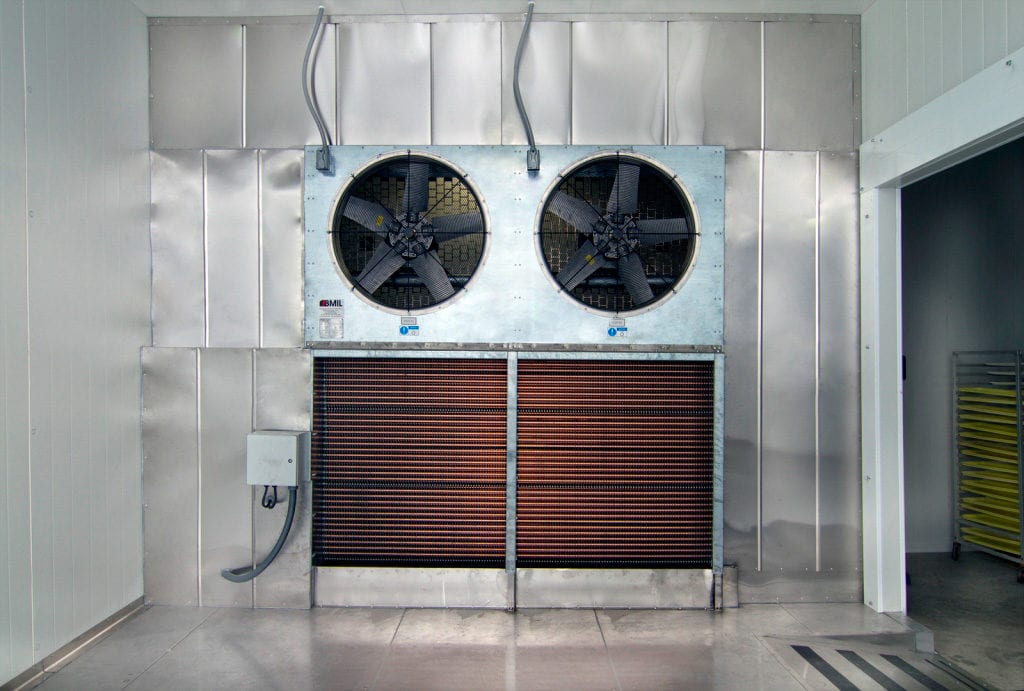

Blast Chillers and Freezers

Temperature control, especially cold storage, is an often misunderstood and neglected control point in the safe preparation and holding of food. Conventional storage refrigerators are not designed to cool food rapidly, but blast chillers are.

Air-blast chillers and freezers are the most economical and practical method of blast chilling and freezing. With capabilities of freezing at rates of 2,000 pounds per hour, PowerBlast offers the option to automatically change between holding and freezing to prevent product damage and lower operating cost.

PowerBlast is flexible with exceptionally fast changeover. It offers the ability to quickly change products, blast times, blast methods, and blast temperatures, and can be custom made to fit any application. PowerBlast can operate in numerous modes, including individual quick frozen, brine freezing in tubs, batch freezing or conveyer freezing, batch chilling or conveyer chilling, and palletized products with air flow spacers.

Blast Chiller Fast Facts

- Quickly chill cooked foods through the bacteria Danger-Zone of 140ºF–40ºF (60ºC–4.4ºC).

- Reduced bacterial growth allows for increased storage life of food.

- Preserve food flavor, texture and color to avoid refrigeration flavor damage.

- Helps meet HACCP (Hazard Analysis Critical Control Point) requirements.

- The most common time frame selected to pass through the Danger-Zone is 4 hours.

- Product final temperature should be defined at the product core.

- When product core reaches final temperature, the outer surfaces will be colder than the core.

- When blast chilling to temperatures of 40ºF (4.4ºC) and lower, the product outer surfaces may freeze.

- Freezing of the product outer surfaces can be avoided, but this increases capital cost.

Blast Freezing Fast Facts

- Starts with the blast chilling elements, but carries on to freezing the product into a solid form.

- Preserves food flavor, texture and color for much longer than blast chilling.

- The most common time frame selected to freeze the product is 4 hours.

- Product final temperature should be defined at the product core.

- When product core freezes,outer surfaces will be much colder than the core.

- Many food products cannot be handled for packaging until they are frozen.

Please read the informative brochure: